aceforever wrote:So does that mean at 1200rpm, at 30% throttle position is essentially full throttle?

Basically, an engine pumps air according to its capacity and rpm. If the manifold

pressure is at atmospheric, then the intake of air can be assumed to be unrestricted.

That is, the engine is getting the maximum amount of air it can consume at that

particular rpm. If the throttle is only 30% open at that point, opening it further will

not increase the amount of air drawn into the engine. So, yes, you could consider

the throttle to be effectively wide open (at that rpm) for any opening 30% or higher.

Is this what people say when a car's throttle response isn't linear? Is this a reason

for electronically controlled TBs?

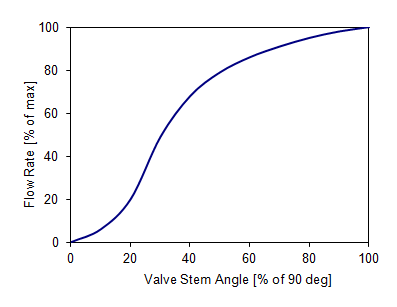

Here is a typical flow vs opening curve for a butterfly valve...

As you can see it is not a straight line relationship. About 80% of max flow is

achieved before the valve is half open. This conflicts with the human expectation

that the car should go faster the further down you press the gas pedal. The rapid

increase in flow before the throttle is half open creates the impression that the

engine has plenty of

POWAH !! But the driver also likes to know he has power in

reserve for overtaking. So he/she is not happy with a car that feels like it has run out

of puff when the pedal is pushed to the floor.

There are various ways of playing with the throttle linkages and the shape of cable

quadrants to try and create a more linear power curve. However, fly-by-wire throttles

allow the ECU to intervene between the movement of the throttle pedal and the

butterfly... by programming the throttle response characteristics.

In your example scenario where at the a higher RPM when 50% throttle would restrict

the air intake. Does that mean MAP sensor would detect it or would it not? I'm thinking

because there is air restriction, there's a little bit of vacuum?

In an intake manifold and ITB assembly, the ideal would to be to have the manifold

pressure just start to drop below atmospheric when the engine reached maximum

rpm's. That is to say, the throttle plate would exercise some degree of control over

manifold vacuum all the way from idle to redline. If the throttles are oversized, they

lose control authority early, and the the engine functions more like a diesel.

The resistance to flow within the intake varies with the velocity, and with the degree

of obstruction provided by the throttle plate. Therefore, while 30% TPS might give

atmospheric at 1200rpm, at 5000rpm it might require 50% TPS to give atmospheric.

Even with the throttle plate at 100%, at redline the velocity may be high enough to

generate a small pressure drop of 1 or 2 kPa. The MAP sensor will pick this up, just

as it picks up the pressure drop caused by my filter at high rpm. You can see this in

the second graph I posted above... with WOT the MAP signal drops towards redline.

jondee86 wrote:They are too big for a 1600cc engine (blacktop ITB's are worse),

and the result is that I ended up having to use TPS load sensing.

Why did Toyota fit oversized ITBs? Seems odd that they would do that.

Based on some forums, the ST ITBs are 42mm and BT ITBs are 45mm. Mine are 35mm

so I'm guessing they're a bit better for less aggressive cams?

This quote from Jenvey might be helpful, as they know a thing or two about ITB's..

What is the best throttle body diameter ?

Factors influencing size are; Power output, RPM, cylinder head design, cylinder

capacity, position of the throttle body in the inlet tract and position of the injector.

Choice of bore size is a balanced compromise resulting from the following;

1) A larger bore leads to lower flow resistance, but obeying the laws of diminishing returns.

2) A smaller bore leads to better throttle control and response (never underestimate)

and improved fuel mixing.

3) The system should be considered in total - from (at least) trumpet flange to cylinder

and proportioned accordingly.

Basic references for BHP per cylinder, assuming ca 120mm from butterfly to valve head

and a max of 9,000 rpm are;

Up to 30 BHP - 30mm Bore

Up to 33 BHP - 32mm

Up to 39 BHP - 35mm

Up to 46 BHP - 38mm

Up to 51 BHP - 40mm

Up to 56 BHP - 42mm

Up to 65 BHP - 45mm

Up to 74 BHP - 48mm

Up to 80 BHP - 50mm

Up to 87 BHP - 52mm

Up to 93 BHP - 54mm

These power figures may be increased by up to 10% in a purpose designed and well

proportioned system.As butterfly to valve distance increases, butterfly size will need

to increase in proportion to system taper and vice versa. Lower revving engines and

those with injectors placed before the butterfly will generally accept a larger body.

So in round figures ST ITB's are good for 220hp and BT good for 260hp. Bolting either

onto a 110hp bigport is overkill. You are better off with your 35mm throttles, and this

is probably why you can get a bit more manifold vacuum than I get with ST ITB's.

Cheers... jondee86