from another forum wrote:how about making a flow test of the versions with and without TVIS delete? I know it's a lot of work but might be worth it to see a tendancy as well as difference between the outer and inner ports.

Also in this case staggered intake lenghts (trumpets) might be an option.

I'm not sure if I'm chasing imaginary, or real results.... as I said I'll be asking more from a few people I confer with.

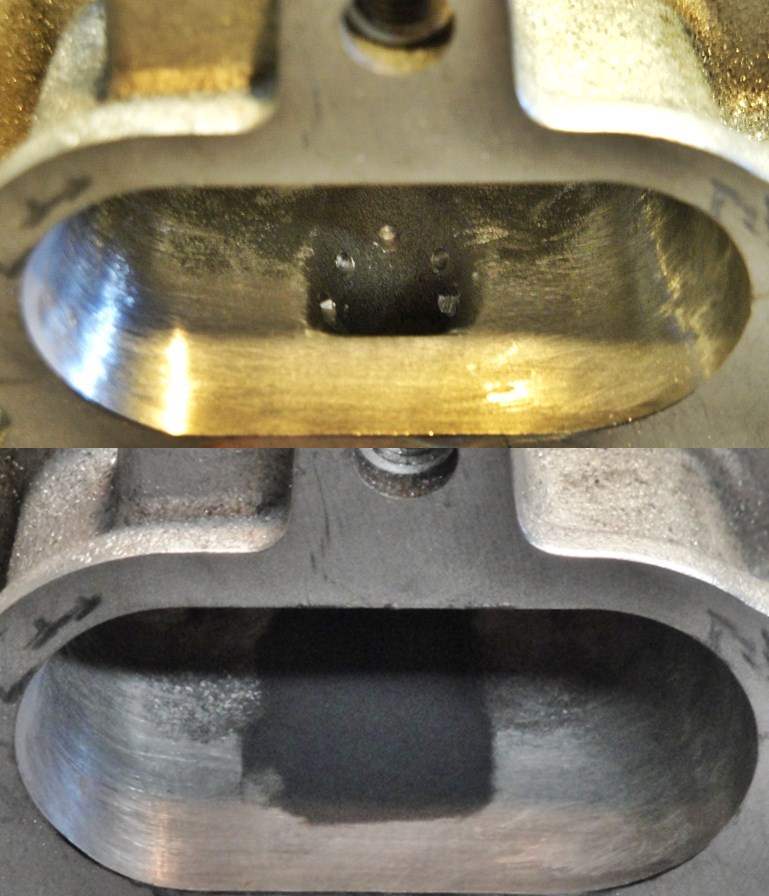

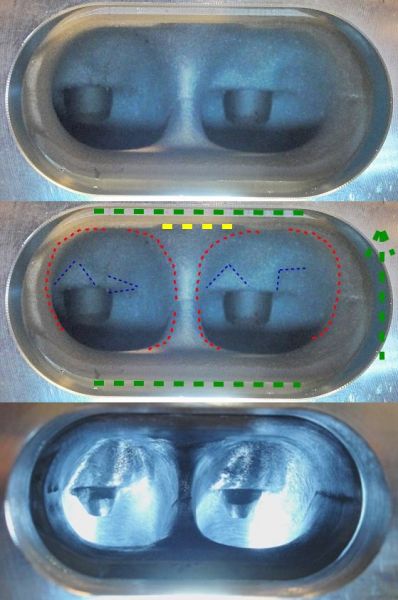

As can be seen below, and as noted in the above post, the entire intake needs to be manipulated/adjusted, and then blended as one

black arrows - show direction of incoming air

solid blue lines - show areas to be ported

dashed blue line represents - the amount the manifold needs to be moved up.

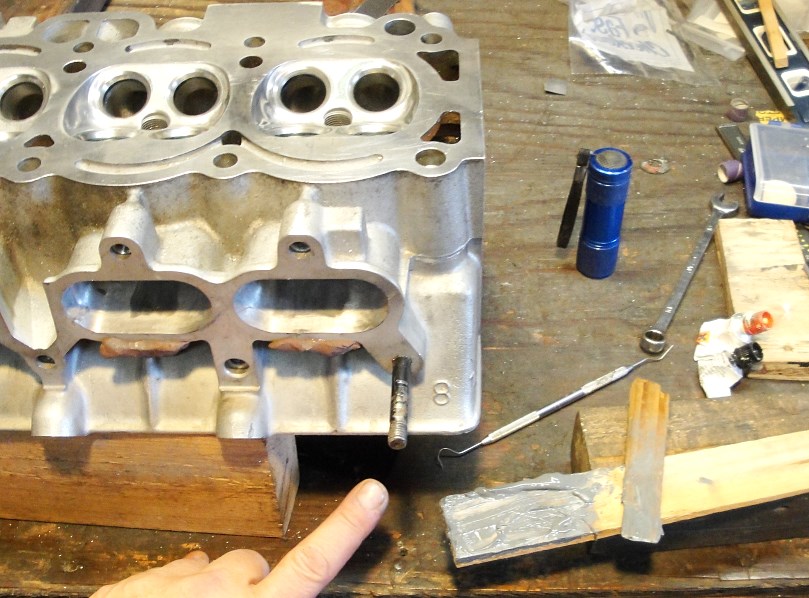

So it is vital to determine the actual location of the manifold... in relation to the T3 delete plate, and then once they are mounted as one, to determine the T3 plate on the head.

So using 2 long bolts I fasten the manifold to the T3 plate set them as carefully as I can ( aligning the bottom port edges to be as flush as possible through all 4 ports) and them tightening the bolts to lock the 2 together.

Then I pick 2 points in the flange, one between cyl 1 and 2, the other between 3 and 4, that I can drill 2 small (3/32") holes... through the manifold and into the T3 plate. Then, using 3/32" x 1" roll(tension) pins I mount the manifold to the T3 plate in one place.

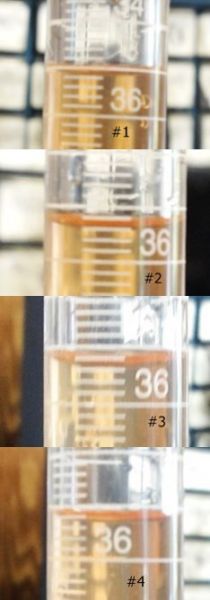

{note far left port in manifold(bottom in photo) has been ported to size, while the other 3 ports await...}

This, the roll pin mounts, will allow me to repeatedly mount and dismount the manifold from the T3 plate and then reaffix them in the same place, time after time.

As is typical with the T3 plate it is the overall size of the gasket... NOT the port...

so when laid over the intake... you can see the bottom edge, and the top edge of the head are in the airstream. The T3 plate is well situated horizontally. So as with the other T3 products I've worked, jack screws are added, and I'll be elongating the T3 mount holes to allow me vertical adjustment with the jack screws.

More to come.....