Page 1 of 1

Rough edges around combustion chambers

Posted: Fri May 10, 2019 8:49 am

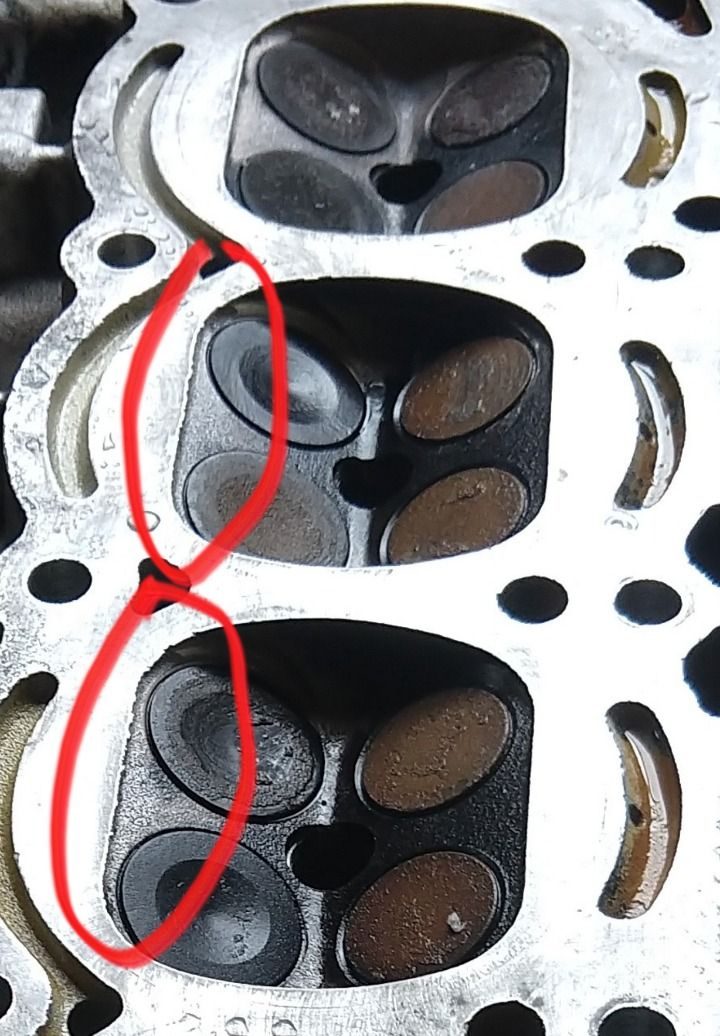

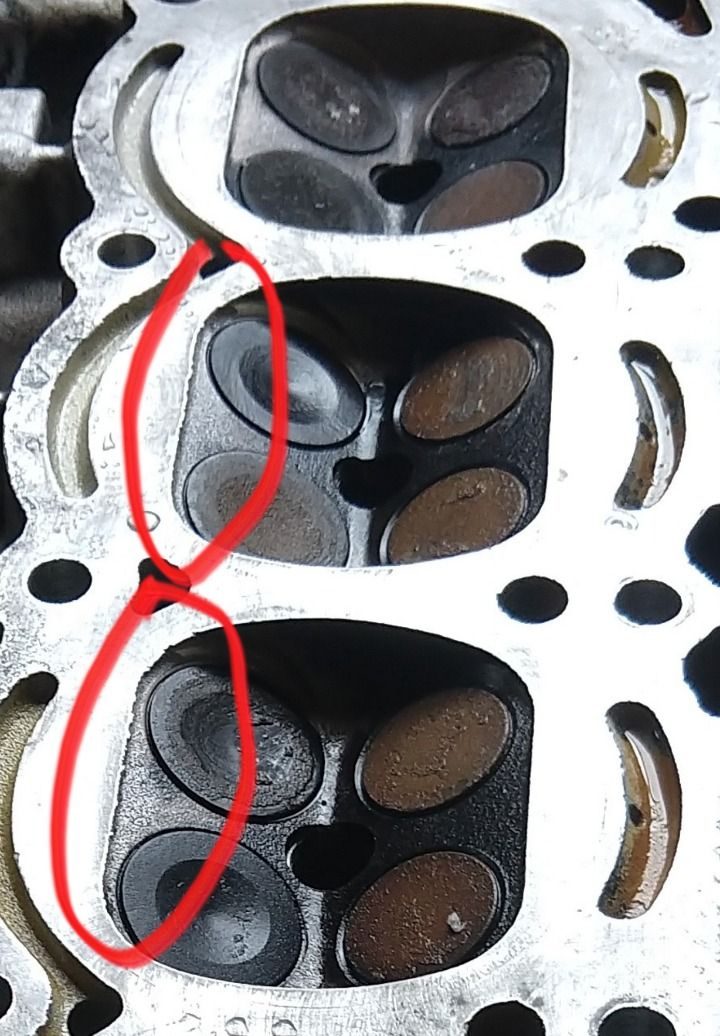

by Franken_Hachi

I have noticed that the edges around the combustion Chambers are rough. my question is, are there any advantages to smoothing out the rough spots. I believe I heard it one point that rough edges like that can create hot spots within the chamber. I have the head off due to a blown head gasket. I have ran a straight edge and feeler gauges on the block and the head and both are within .001 of an inch. I plan on using the TRD head gasket which should up the compression , and I am concerned about detonation. Here is a picture of the cylinder head and the area in question.

Re: Rough edges around combustion chambers

Posted: Fri May 10, 2019 9:42 am

by sirdeuce

Oh yeah, a smooth combustion compartment, head and pistons really reduces the chance of detonation, especially at higher compression levels. A steady hand and a Dremel can get the job done. Do a bit of research to see just where and how much work needs to be done. Don't go ape **** on it right out the gate. Also be sure you have a balance between your chamber volumes when your are done. Don't think all of the above will apply if you are just looking to clean the edges you have circled, you can get that little bit done with emery cloth/paper. Either way, make sure ALL abrasive material is removed, just one little piece can destroy a cylinder wall.

On the matter of using a thinner MLS gasket, your mating surfaces need to be smooth, smoother than flycutting or belt sanding can offer. Make sure the shop you choose to do the work is capable of delivering. Case of the block surface? It can be done by hand with a very flat and straight piece of steel. The plate needs to be relatively heavy so all you do is move it around, let the weight do the work. Take long strokes in every direction. I would say sand in circles but that gats a little iffy by hand and there is a better chance of gripping the plate causing an uneven pressure. take you time, be patient and it can work out. The head can be done the same way, but the aluminum will go so much faster. Watch it closely. Check your surfaces with a straight edge. I have done it successfully on an engine I didn't want to remove. It's a PITA, but unless you are good with the whole removal and disassembly of you engine, which almost always winds up being a rebuild, I would take my time on this or just keep a stock gasket for now, unless somewhere out there you can find a composite gasket that is thinner.

Re: Rough edges around combustion chambers

Posted: Fri May 10, 2019 11:19 am

by oldeskewltoy

I don't use a Dremel on this - too much chance of damaging the surface.

I would recommend a #2 flat blade screw driver gripped in the hand(wrapped around the screwdriver shaft) so only the edge of the screw driver blade sticks out of your hand. Gently run the edge (not the tip) of the screwdriver around the chambers edge keeping the screwdriver at about a 45 degree ange... OR if you can get one... a de-burring tool works pretty well too

Re: Rough edges around combustion chambers

Posted: Fri May 10, 2019 11:23 am

by Franken_Hachi

My dad is a retired Machinist. I should be heading up his way Sunday. I didn't even think about that.

Re: Rough edges around combustion chambers

Posted: Fri May 10, 2019 12:45 pm

by UNLIMITED 86

Im with OST on this one. I wouldn't use a dremel either.

You dont need/want to remove much material. Like you said, you just want to eliminate potential hot spots and it doesn't take a lot to remove those high points around the edges.

If your dad's an ex machinist, tell him you just want to deburr the edges. I bet he will knock it out before your mom has a chance to put her flowers in a vase.

Re: Rough edges around combustion chambers

Posted: Fri May 10, 2019 12:49 pm

by Franken_Hachi

I wish my mom was putting flowers in a vase.

Re: Rough edges around combustion chambers

Posted: Fri May 10, 2019 1:17 pm

by UNLIMITED 86

Same here. Sorry for assuming.

Re: Rough edges around combustion chambers

Posted: Sat May 11, 2019 4:14 am

by davew7

Search Cometic gaskets. They have several thinner or thicker MLS head gaskets for the 4AGE. If you want to use a Dremel tool to de-burr, use one of the small sanding drums. Or just use sand paper to knock off the burrs. Less chance of screwing up the head surface. You just need to do a really good job cleaning the head after de-burring. If you want to go for over-kill, get a Cratex kit and polish the head chambers. davew7

Re: Rough edges around combustion chambers

Posted: Sat May 11, 2019 5:51 am

by Rogue-AE95

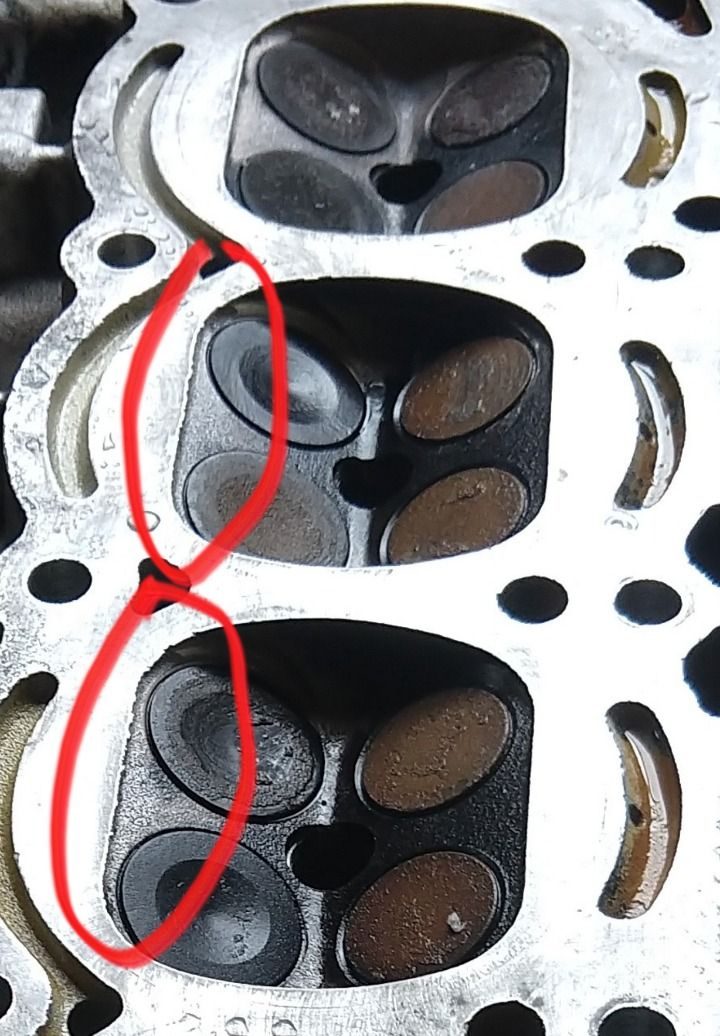

Whatever you do, don't do this:

(Bigport head from a disassembled 4A-GE that I had bought, didn't see the head until after I bought everything.)

Re: Rough edges around combustion chambers

Posted: Sat May 11, 2019 6:19 am

by Franken_Hachi

I used an o-ring pick to run around the edge, it did not have a sharp edge but it knocked off the burrs. Thank you everyone for the advice.

Re: Rough edges around combustion chambers

Posted: Sat May 11, 2019 9:21 pm

by UNLIMITED 86

Rogue-AE95 wrote:Whatever you do, don't do this:

(Bigport head from a disassembled 4A-GE that I had bought, didn't see the head until after I bought everything.)

This is why you don't want to use a dremel or any other powered tool.

Looks like they started by deshrouding the valves but gave up after they probably realized that they destroyed the head.

Re: Rough edges around combustion chambers

Posted: Sun May 12, 2019 8:13 am

by Franken_Hachi

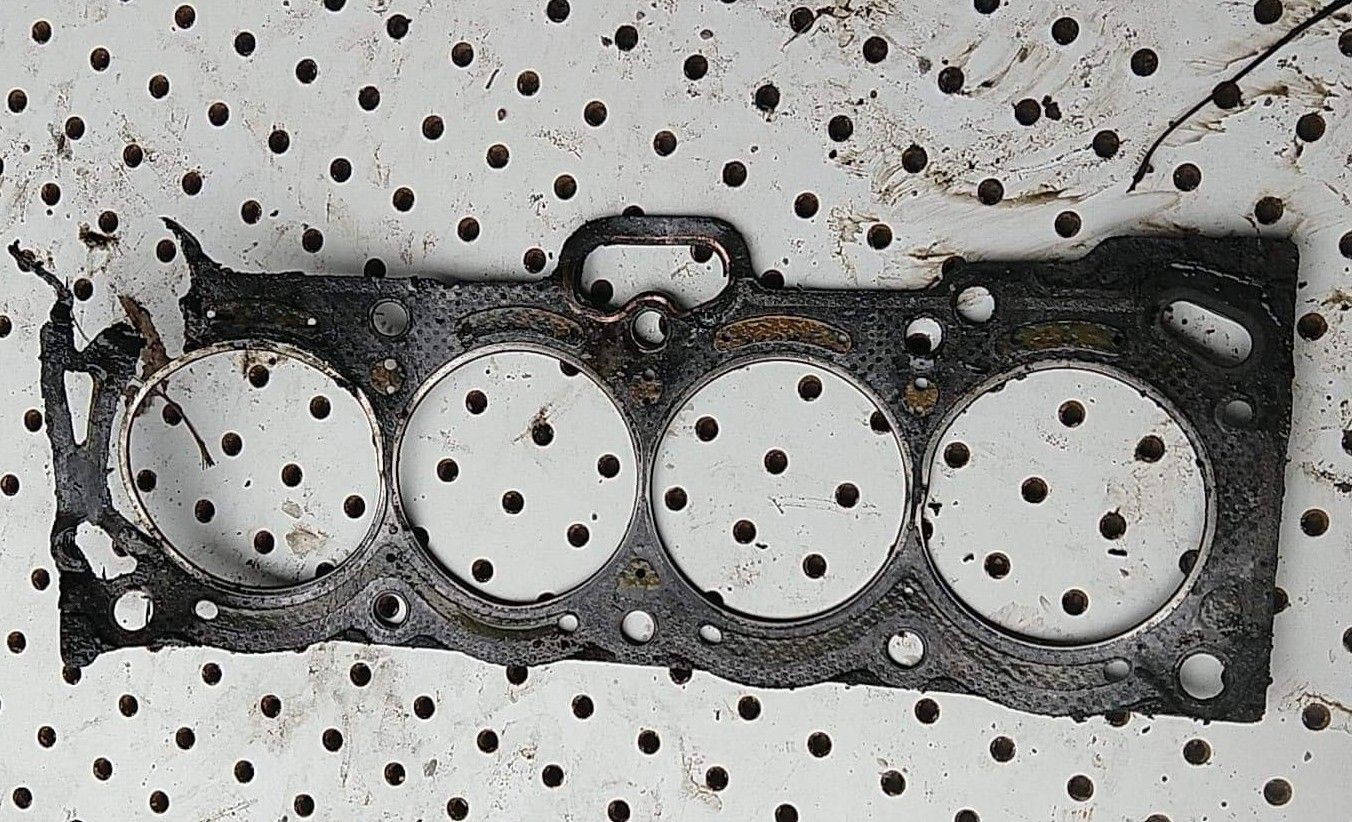

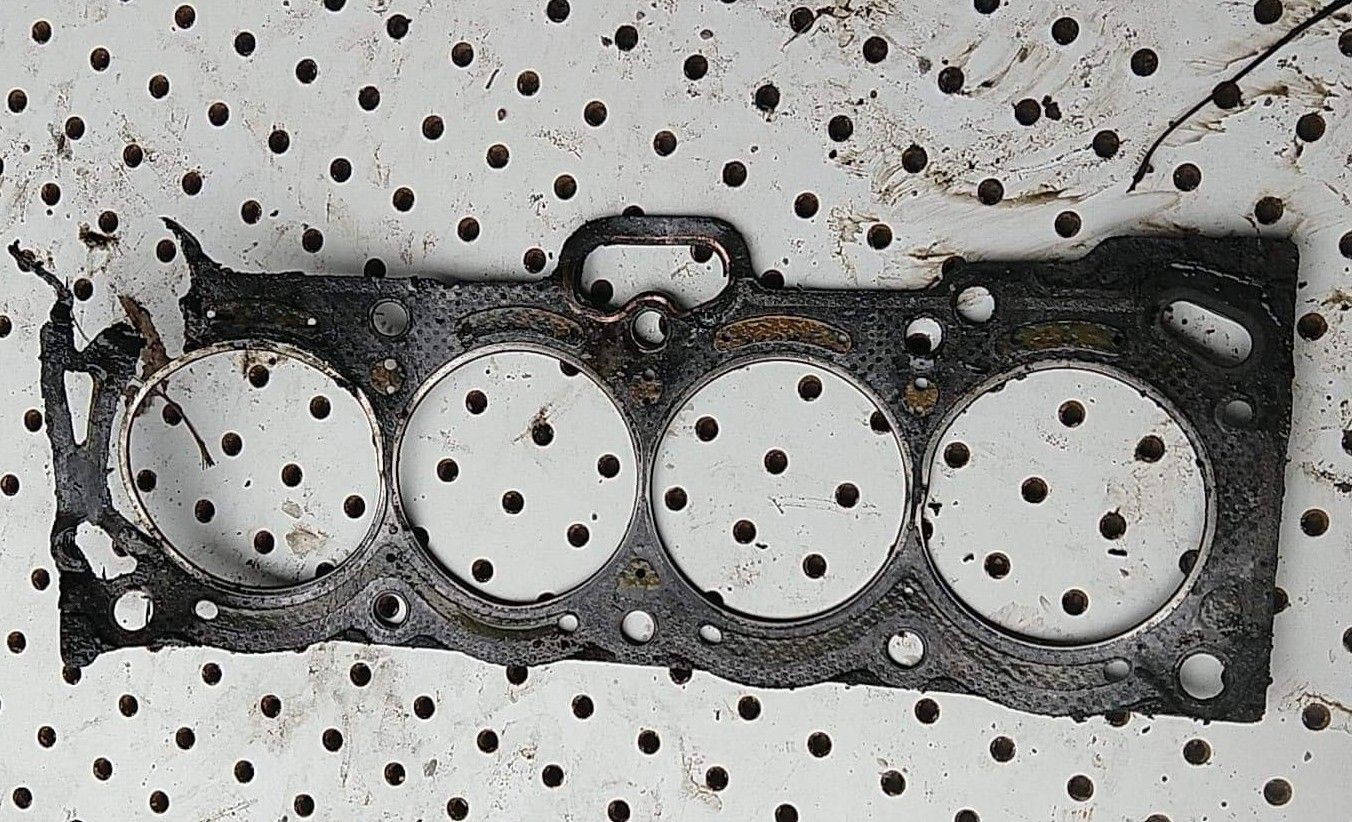

There are pics of the head gasket and the tool I used to clean the edge of the combustion Chambers.

These picks are all so amazing when you are disassembling a dashboard.

These picks are all so amazing when you are disassembling a dashboard.

Re: Rough edges around combustion chambers

Posted: Mon May 13, 2019 3:43 am

by davew7

To clean the combustion chamber, just go to the local Ace hardware and buy a 1" Dia. wire bush, made from (((.009" wire))) set in a cap with a 1/4" shaft. The fine wire can clean the surface, without leaving marks in the aluminum when using a die grinder or drill motor. The only place you have to scrape is the small radius in valve relief pocket in the pistons. davew7

Re: Rough edges around combustion chambers

Posted: Mon May 13, 2019 5:40 pm

by sirdeuce

I just use my "Dremel" with a 1/2" barrel and 100 grit sleeve for things like this. Never thought about something like a deburring tool for the job.