4AG Turbo oil loss ?

Re: 4AG Turbo oil loss ?

I think I like Jondee86's advice with baffled breathers. I don't plan on reusing anything caught in the catch can. I'm planning on running a baffled breather on each valve cover to a catch can with a breather on top of the can. Do I need to plumb the outlet of a can to the intake, or would that cause more pressure? It just seems as though it would help pull the blow by gases from the engine.

Re: 4AG Turbo oil loss ?

4agtee wrote:Do I need to plumb the outlet of a can to the intake, or would that

cause more pressure?

There is a slight negative pressure in the duct between the air filter and

the turbo inlet. Venting the can into the inlet will get rid of of the fumes

and that "hot engine" smell while waiting at the lights.

Either way, you need to make sure that you have more area in the outlet

than you have in the two inlet hoses. That is, if you have 2 x 12mm dia

inlet hoses, you need an 19mm (3/4") dia outlet hose or breather. Some

hose fittings have an ID quite a bit smaller than the hose, so try and

maintain the full bore size. If in doubt go up one size on the hose.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: 4AG Turbo oil loss ?

So 1 12mm breather hose from each valve cover, 1 breather filter on the 2liter can, and a 19mm hose from the can to the inlet?

Re: 4AG Turbo oil loss ?

It's an either or situation. If you put a filter-breather on the can you don't

need the hose from the can to the inlet. The fumes just vent to atmosphere

via the filter-breather. These guys seem reasonable...

http://www.neukin.com/Oil_Catch_Can_p/oilcatchcan_r.htm

Cheers... jondee86

need the hose from the can to the inlet. The fumes just vent to atmosphere

via the filter-breather. These guys seem reasonable...

http://www.neukin.com/Oil_Catch_Can_p/oilcatchcan_r.htm

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: 4AG Turbo oil loss ?

So, did my crankcase over pressurize due to a restrictive breather system (oem intake valve cover breather port) and small volume capacity catch tank- inhibiting oil draining from my turbo? Or the fact that it was plumbed back to the intake? I'm confused...

Re: 4AG Turbo oil loss ?

4agtee wrote:So, did my crankcase over pressurize due to a restrictive breather system

(oem intake valve cover breather port) and small volume capacity catch tank

inhibiting oil draining from my turbo? Or the fact that it was plumbed back to

the intake? I'm confused...

Firstly, there is no way to tell from a distance if your turbo has in fact "failed",

or if it has just passed more oil thru the seals than it should. A "small puff of

smoke at sudden WOT" does not sound like a "blown turbo" to me, although

I am the first to admit I am not a turbo guy.

So in reviewing the various factors that could contribute to oil flooding in the

turbo, we seem to be agreed that the oil supply is within spec and the oil drain

also complies with accepted practice. That being the case, providing the turbo

is is good mechanical condition, the last factor to be considered is the possible

pressurizing of the crankcase.

As blowby increases with the amount of power the engine is producing and the

rpm at which it is running, it is reasonable to assume that your engine will be

producing more blowby than a stock N.A. engine. This leads to the possibility

that you need more venting than provided by the single factory cam cover vent.

So right now we are talking about running a vent hose from each cam cover,

and the vent size to be at least as large as the standard vent.

Both vent lines need to be connected to a catchcan to collect and condense oil

vapor and other contaminents carried by the blowby gases. The "cleaned" gases

can either be vented to atmosphere by way of a filter-breather on top of the

catchcan, or they can be vented into the engine intake ducting after the air

filter to be burned. The only requirement is that the vent hose be large enough

that it does not become a restriction.

Backpressure in the crankcase can only be caused if the venting hoses are too

small to carry the volume of blowby at high load/rpm engine operation. The

small amount of negative pressure in the engine air intake is not enough to

have any worthwhile "suction" to help extract the crankcase gases.

Lastly, and again, I am not in a position to know this for sure, I suspect that

snapping the throttle open at low rpm's (turbo not in boost) will most likely

expose the compressor to a short period of increased negative pressure. And

this may well cause a small amount of oil to be sucked thru the compressor

oil seal before the turbo starts to spool and build pressure.

My understanding is that when the tubo is not boosting, the inlet tract is

operating at some level of vacuum, just like a N.A. engine. Maybe someone

more familiar with turbo operation could comment on these points

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: 4AG Turbo oil loss ?

Vent to atmosphere it is.

+1 for jondee86

Thanks for your help man.

+1 for jondee86

Thanks for your help man.

Re: 4AG Turbo oil loss ?

jondee86 wrote:The only requirement is that the vent hose be large enough

that it does not become a restriction.

Backpressure in the crankcase can only be caused if the venting hoses are too

small to carry the volume of blowby at high load/rpm engine operation. The

small amount of negative pressure in the engine air intake is not enough to

have any worthwhile "suction" to help extract the crankcase gases.

My understanding is that when the tubo is not boosting, the inlet tract is

operating at some level of vacuum, just like a N.A. engine. Maybe someone

more familiar with turbo operation could comment on these points

Cheers... jondee86

Part of the problem with the setup posted earlier is not only the small single valve cover pcv (and line), but also the long length of the line from the pcv to vacuum source (it's ran across the engine bay and back). Definitely a restriction.

jondee86 is absolutely right about the negative manifold pressure (vacuum). I've had a boost gauge before that shows vacuum readings. Manifold vacuum will be at it's highest when the rpm is high, and the throttle plate is closed. On oem setups they often place a pcv valve (or line running from the valve) directly behind the throttle plate on the manifold using as short a line as possible from the source for added velocity. This helps pull all the nasty vapor out of the crankcase as the manifold vacuum increases.

VTA is ok as long as it's not restrictive. In addition to having large enough ports/lines/vent/can/etc.... can and line placement is important. Having the lines as short as possible, and pointing up from from the valve cover ports to the ports on the can would be ideal (no low spots for oil to pool in the line). That way the hot crankcase vapor can take the path of least resistance and move up / out, and any oil that doesn't make it to the can can easily drain back into the valve cover.

Think of draining your engine oil or coolant without removing oil fill cap or radiator cap... OR the difference between turning a jug of liquid upside down to pour it out, vs. doing the same and poking a hole in the bottom.... The point? Fluid always drains easier with an air vent hole. Hopefully VTA'ing your setup properly will have a similar affect.

VTA is a little annoying on a street car because you always smell (and smell like) oil. It can also be harder on seals, and it's probably not a good idea on a new or newly rebuild engine - apparently the vacuum draw helps with ring seal.

It's also worth mentioning that a proper external oil drain (e.g. smallport setup) might help a lot. Only thing is you'd probably have to drill the big port head to achieve the same affect since the smallport drain is gravity fed.

Looking for clues at the scene of the crime...

Just while I am thinking about it... you say you did not get any oil in your

catchcan, and your hoses look like brand new Normally the hoses finish

Normally the hoses finish

up brown and crusty looking because oil vapor coats the inside. So either

you took the picture just after you fitted the catchcan system, or your engine

is in such good condition, it doesn't have any blowby

If you take the hose off the connection to the intake duct, you should be able

to feel something coming out the end when the engine is running... unless

there is a blockage in the system.

Cheers... jondee86

catchcan, and your hoses look like brand new

up brown and crusty looking because oil vapor coats the inside. So either

you took the picture just after you fitted the catchcan system, or your engine

is in such good condition, it doesn't have any blowby

If you take the hose off the connection to the intake duct, you should be able

to feel something coming out the end when the engine is running... unless

there is a blockage in the system.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: 4AG Turbo oil loss ?

I should have taken pictures when I drained my catch can the last 2 times...

There wasn't a large amount of oil in the can. A little bit oil and water mixed sludge at the bottom, but was only 1/5 of what was in the can- the rest being water from condensation. The amount being less than a 1/3 of the cusco unbaffled catch can.Because there was no baffle, could this mean that oil was getting sucked right back into the intake? If the can caught the condensation, why didn't it catch oil if in fact it was coming from the engine?

My hoses would get a little sludgy light vanilla cream color leaving crap on the inside of the hoses, but not enough to cause restriction. Crankcase pressure would still leave the catch can outlet hose to the intake when disconnected while the engine was running. Those hoses used to have less color than they do now, since they were exposed to heat in the engine bay.

Oil in the can was not proportional to the amount of engine oil I was losing.

There wasn't a large amount of oil in the can. A little bit oil and water mixed sludge at the bottom, but was only 1/5 of what was in the can- the rest being water from condensation. The amount being less than a 1/3 of the cusco unbaffled catch can.Because there was no baffle, could this mean that oil was getting sucked right back into the intake? If the can caught the condensation, why didn't it catch oil if in fact it was coming from the engine?

My hoses would get a little sludgy light vanilla cream color leaving crap on the inside of the hoses, but not enough to cause restriction. Crankcase pressure would still leave the catch can outlet hose to the intake when disconnected while the engine was running. Those hoses used to have less color than they do now, since they were exposed to heat in the engine bay.

Oil in the can was not proportional to the amount of engine oil I was losing.

Re: 4AG Turbo oil loss ?

The pcv condensation is more common when you're only doing short trips in cool weather since the oil doesn't heat up enough to evaporate it. Placing the can in a place where it's exposed to more heat will help lessen the affect. Shorter lines will also help for retaining heat, and larger lines will be harder to clog. I've even seen air / oil separators that circulate coolant to help prevent the build up of the condensation sludge.

No catch can is perfect (even a good air /oil separtor) since some vapor will always pass through, but having some type of baffling is far superior, otherwise the vapor can just go right in (and out) of the can. If the gas / fuel vapor is still airborne, and doesn't get trapped in the water droplets, then it can pass through the can easier.

It's possible you're loosing oil another way... how often are you having to add oil?

No catch can is perfect (even a good air /oil separtor) since some vapor will always pass through, but having some type of baffling is far superior, otherwise the vapor can just go right in (and out) of the can. If the gas / fuel vapor is still airborne, and doesn't get trapped in the water droplets, then it can pass through the can easier.

It's possible you're loosing oil another way... how often are you having to add oil?

Re: 4AG Turbo oil loss ?

There were a lot of short trips in cold weather, which explains the condensation.

Over the course of the 3000 miles going coast to coast, I spent about damn near a 5 gallon jug of oil.

What is the other way you suspect I am losing oil?

Over the course of the 3000 miles going coast to coast, I spent about damn near a 5 gallon jug of oil.

What is the other way you suspect I am losing oil?

Re: 4AG Turbo oil loss ?

The oil that you are losing will not be going thru your catchcan, even if

it is the type without baffles. It is possible to make a catchcan out of an

empty plastic 1.5 liter drink bottle with a hole beside the neck to poke

the end of your vent hose into. Leave the screw top off and it will catch

any oil that leaves the engine in droplet form. Not very efficient, but it

will do a job

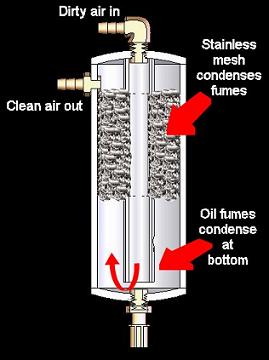

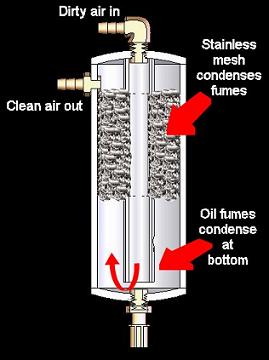

Here is a drawing of a catchcan that incorporates most of the desirable

features for efficiently capturing blowby contaminents...

First, there is an entry tube that drops to near the bottom of the can.

The tube will have holes along its length so that if the end becomes

submerged, it does not foam up the liquid in the bottom of the can.

Inertial separation takes place as the gas flow changes directionat the

tube outlet.

Second, the can contains loose mesh similar to a pot scrubber, to catch

the smaller droplets and any spray raised from the liquid surface below.

Separation occurs by a combination of condensing, viscous impingement

and inertial separation as the slow speed gas flow if forced to change

direction many times while passing thru the mesh.

Baffles will also do a job, but mesh will work better. You also need to

look at the size of the hole in the entry and exit fittings, as often, the

hole size can be a lot smaller than the hose inside diameter, creating

a restriction.

Cheers... jondee86

it is the type without baffles. It is possible to make a catchcan out of an

empty plastic 1.5 liter drink bottle with a hole beside the neck to poke

the end of your vent hose into. Leave the screw top off and it will catch

any oil that leaves the engine in droplet form. Not very efficient, but it

will do a job

Here is a drawing of a catchcan that incorporates most of the desirable

features for efficiently capturing blowby contaminents...

First, there is an entry tube that drops to near the bottom of the can.

The tube will have holes along its length so that if the end becomes

submerged, it does not foam up the liquid in the bottom of the can.

Inertial separation takes place as the gas flow changes directionat the

tube outlet.

Second, the can contains loose mesh similar to a pot scrubber, to catch

the smaller droplets and any spray raised from the liquid surface below.

Separation occurs by a combination of condensing, viscous impingement

and inertial separation as the slow speed gas flow if forced to change

direction many times while passing thru the mesh.

Baffles will also do a job, but mesh will work better. You also need to

look at the size of the hole in the entry and exit fittings, as often, the

hole size can be a lot smaller than the hose inside diameter, creating

a restriction.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: 4AG Turbo oil loss ?

5gal @ 3000mi oughta be better then a mosquito sprayer!!!!!

Does the turbo shaft wiggle or does it not wiggle more then 1mm?

Does the turbo shaft wiggle or does it not wiggle more then 1mm?

Re: 4AG Turbo oil loss ?

Yeah I know.. That's a lot of oil.

Shaft play seemed normal(even @ idle), but I'll take my intake off and use a dial indicator to get precise measurements..

So jondee86, will it be more beneficial to Vent the can to atmosphere or reroute the hose to intake(I thought the benefits were negligible...)?

Shaft play seemed normal(even @ idle), but I'll take my intake off and use a dial indicator to get precise measurements..

So jondee86, will it be more beneficial to Vent the can to atmosphere or reroute the hose to intake(I thought the benefits were negligible...)?

Re: 4AG Turbo oil loss ?

That's a lot of oil loss. Auto Manufacturers generally accept up to 1 quart every 3000 miles (and even that's a bit much imo).

I agree about what jondee86 said. A catch can baffle is much less important on a vta setup since the oil doesn't get routed back to the intake. I actually used to just run a line from the stock pcv to an empty beer can with some holes poked in it on an n/a engine . It smelled like oil all the time though, my seapy oil seals leaked even worse, and I had to cap oil changes at 2 month intervals even though the car sees less than 1k miles during that amount of time.

. It smelled like oil all the time though, my seapy oil seals leaked even worse, and I had to cap oil changes at 2 month intervals even though the car sees less than 1k miles during that amount of time.

Here a baffled example without removable filter media:

Normally I'd say reroute on a street car since you're not in boost most of the time. But since you're not using a pcv valve (and the manifold as a vacuum source) it's not as big of a difference. Further, since you're loosing a ton of oil anyway it's probably best to vta to help help rule things out.

I agree about what jondee86 said. A catch can baffle is much less important on a vta setup since the oil doesn't get routed back to the intake. I actually used to just run a line from the stock pcv to an empty beer can with some holes poked in it on an n/a engine

Here a baffled example without removable filter media:

Normally I'd say reroute on a street car since you're not in boost most of the time. But since you're not using a pcv valve (and the manifold as a vacuum source) it's not as big of a difference. Further, since you're loosing a ton of oil anyway it's probably best to vta to help help rule things out.

Re: 4AG Turbo oil loss ?

Interesting design ^^^^ of can there. The tangential entry is helpful

in separating oil drops by having them get flung against the wall as the

gas swirls around. The gas then goes IN to the lower filter and OUT of

the upper filter. Those filters could be the same or different, and quite

possibly are of similar construction to pleated fabric air filters. There

are a hundreds of different designs around, so it becomes a question

of finding one you like that will fit in the available space.

The only reason blowby gases get routed back into the engine intake is

to satisfy emissions regulations. There is no benefit to the engine (in

fact it can be detrimental) but it does help the environment

Cheers... jondee86

in separating oil drops by having them get flung against the wall as the

gas swirls around. The gas then goes IN to the lower filter and OUT of

the upper filter. Those filters could be the same or different, and quite

possibly are of similar construction to pleated fabric air filters. There

are a hundreds of different designs around, so it becomes a question

of finding one you like that will fit in the available space.

The only reason blowby gases get routed back into the engine intake is

to satisfy emissions regulations. There is no benefit to the engine (in

fact it can be detrimental) but it does help the environment

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: 4AG Turbo oil loss ?

Just in case any members have stumbled across this thread seeking answers on how to design their valve cover baffles for installed breather fittings, proof is here on what works.

http://mewagner.com/?page_id=1221

http://mewagner.com/?page_id=1221

-

NH-hillbilly

- Club4AG Regular

- Posts: 31

- Joined: Fri Sep 11, 2015 11:18 am

Re: 4AG Turbo oil loss ?

what are your impressions of that turbo on this motor?