7AGE build

- speedmaster

- Club4AG Expert

- Posts: 234

- Joined: Tue Jan 22, 2013 9:44 pm

- Location: Malaysia and Brunei

- Contact:

7AGE build

Im starting my 7A build next month. Stuffs i can get for the 7A block ar 1zz crankshaft, ca18det pistons and so on. Anyone here have experience in fitting the 1zz crankshaft? Do i need to do any machining in order for the crankshaft to sit in? The crankshaft will fit 20v 8.5" clutch am i right? I cannot get a 2zz rods at the moment but any other rods could be used? I was told B18 Honda and 4G93 mitsubishi rods will fit.

thanks for the time to read this.

thanks for the time to read this.

Visit my FB fan page at https://www.facebook.com/speedmasteracing

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

Why not use a 7A crank?

I have heard a lot of talk about these super hybrid motors but have never seen it actually implimented. More importantly can't figure out why anyone would. All the time and money of custom work and experimenting and if you are lucky you might have something almost as good as a 2ZZ.

There are a few simpler options. I can get stroker cranks that will fit in the 4A block. This simplifies things a lot because you don't have to adjust for the taller block. I believe I can also get a better 7A crank. None of those options will be terribly cheap but much simpler than trying to make a mega frankenstein.

What are you trying to do? are you limited to staying with the a motor? Are you limited to displacement? Are you limited to NA? Why try to make such a crazy build?

I have heard a lot of talk about these super hybrid motors but have never seen it actually implimented. More importantly can't figure out why anyone would. All the time and money of custom work and experimenting and if you are lucky you might have something almost as good as a 2ZZ.

There are a few simpler options. I can get stroker cranks that will fit in the 4A block. This simplifies things a lot because you don't have to adjust for the taller block. I believe I can also get a better 7A crank. None of those options will be terribly cheap but much simpler than trying to make a mega frankenstein.

What are you trying to do? are you limited to staying with the a motor? Are you limited to displacement? Are you limited to NA? Why try to make such a crazy build?

Re: 7AGE build

I built a couple 7age motors and I would just stick with the 7a crank. Are you going to boost the car or stay N/A? My advise will depend on your build plans.

- speedmaster

- Club4AG Expert

- Posts: 234

- Joined: Tue Jan 22, 2013 9:44 pm

- Location: Malaysia and Brunei

- Contact:

Re: 7AGE build

v33sonata wrote:I built a couple 7age motors and I would just stick with the 7a crank. Are you going to boost the car or stay N/A? My advise will depend on your build plans.

thanks for the reply

i am going to stay NA with a 20v head. from your experience, whats the maximum rpm you think the 7A block can stand?

Visit my FB fan page at https://www.facebook.com/speedmasteracing

- speedmaster

- Club4AG Expert

- Posts: 234

- Joined: Tue Jan 22, 2013 9:44 pm

- Location: Malaysia and Brunei

- Contact:

Re: 7AGE build

yoshimitsuspeed wrote:Why not use a 7A crank?

I have heard a lot of talk about these super hybrid motors but have never seen it actually implimented. More importantly can't figure out why anyone would. All the time and money of custom work and experimenting and if you are lucky you might have something almost as good as a 2ZZ.

There are a few simpler options. I can get stroker cranks that will fit in the 4A block. This simplifies things a lot because you don't have to adjust for the taller block. I believe I can also get a better 7A crank. None of those options will be terribly cheap but much simpler than trying to make a mega frankenstein.

What are you trying to do? are you limited to staying with the a motor? Are you limited to displacement? Are you limited to NA? Why try to make such a crazy build?

maybe i think its not impossible to build? but then again, we learn from mistakes. if i fail this time then i know this hybrid is a waste of time and money?

It so happens that at this moment, i have all these on hand

7A block rebored 83mm with oil squiters

1zz crank, rod, piston

ca18 piston set

20v cnc ported head

kelford 302/302 10.5mm

valve springs and retainers upgraded

i just need a guide to fit in these stuffs into the 7A block.

Visit my FB fan page at https://www.facebook.com/speedmasteracing

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

There is very little that is impossible to build. Practical or sensible is a whole other thing.

If you are transverse layout I would much rather just throw a 2ZZ in. I did a little research and it doesn't sound easy to find a longitudinal trans for one but there are plenty of other options.

Even with everything you have it would take a good bit of money to get a reliable functional motor. It would take even more to get it to outperform a 4A with the same amount of time and money put into it. That's assuming you go simple and use something like 7A crank and GZE pistons or something like that. Get into all this other stuff and the time and money to performance ratio just doesn't make sense to me.

I'm confidant I could get a V6 or V8 into an 86 for about the same time and money as a well built 7A that made 50% less power.

For less than the cost and time to do the 7A a turbo 4A could be build that would walk on any NA 7A ever built.

If you are transverse layout I would much rather just throw a 2ZZ in. I did a little research and it doesn't sound easy to find a longitudinal trans for one but there are plenty of other options.

Even with everything you have it would take a good bit of money to get a reliable functional motor. It would take even more to get it to outperform a 4A with the same amount of time and money put into it. That's assuming you go simple and use something like 7A crank and GZE pistons or something like that. Get into all this other stuff and the time and money to performance ratio just doesn't make sense to me.

I'm confidant I could get a V6 or V8 into an 86 for about the same time and money as a well built 7A that made 50% less power.

For less than the cost and time to do the 7A a turbo 4A could be build that would walk on any NA 7A ever built.

speedmaster wrote:yoshimitsuspeed wrote:Why not use a 7A crank?

I have heard a lot of talk about these super hybrid motors but have never seen it actually implimented. More importantly can't figure out why anyone would. All the time and money of custom work and experimenting and if you are lucky you might have something almost as good as a 2ZZ.

There are a few simpler options. I can get stroker cranks that will fit in the 4A block. This simplifies things a lot because you don't have to adjust for the taller block. I believe I can also get a better 7A crank. None of those options will be terribly cheap but much simpler than trying to make a mega frankenstein.

What are you trying to do? are you limited to staying with the a motor? Are you limited to displacement? Are you limited to NA? Why try to make such a crazy build?

maybe i think its not impossible to build? but then again, we learn from mistakes. if i fail this time then i know this hybrid is a waste of time and money?

It so happens that at this moment, i have all these on hand

7A block rebored 83mm with oil squiters

1zz crank, rod, piston

ca18 piston set

20v cnc ported head

kelford 302/302 10.5mm

valve springs and retainers upgraded

i just need a guide to fit in these stuffs into the 7A block.

- speedmaster

- Club4AG Expert

- Posts: 234

- Joined: Tue Jan 22, 2013 9:44 pm

- Location: Malaysia and Brunei

- Contact:

Re: 7AGE build

yes, i do believe 4A gives better response over 7A block.

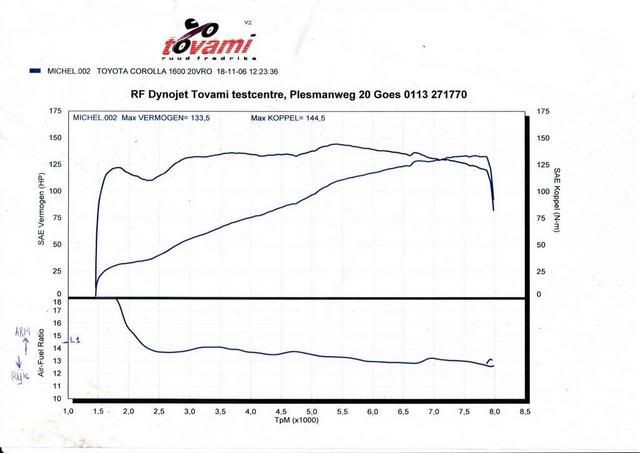

my current 20v is making 171 at wheel, im just trying to RnD and see how durable is the "9age" setup

my current 20v is making 171 at wheel, im just trying to RnD and see how durable is the "9age" setup

Visit my FB fan page at https://www.facebook.com/speedmasteracing

Re: 7AGE build

Gotya. I started a 7a 20v build already too. There is alot that goes into it. the 7a will rev just fine its the rods that become an issue. So you would want to upgrade them. I am using eagle hbeams from a Honda b16. What c/r are you thinking? are you using a BT or ST? You should get a hold of Barry at MRP they have done a bunch of 7a conversions along with others. They know their stuff!

- speedmaster

- Club4AG Expert

- Posts: 234

- Joined: Tue Jan 22, 2013 9:44 pm

- Location: Malaysia and Brunei

- Contact:

Re: 7AGE build

v33sonata wrote:Gotya. I started a 7a 20v build already too. There is alot that goes into it. the 7a will rev just fine its the rods that become an issue. So you would want to upgrade them. I am using eagle hbeams from a Honda b16. What c/r are you thinking? are you using a BT or ST? You should get a hold of Barry at MRP they have done a bunch of 7a conversions along with others. They know their stuff!

yes, Barry gave his opinions as well, very helpful guy. Honda B16 H beams on the 7A crank? Why not go straight for 7A H beams? At the moment using 12.0CR CP pistons. Its a Blacktop.

Visit my FB fan page at https://www.facebook.com/speedmasteracing

Re: 7AGE build

allen... listen. theres a reason a 20v doesnt produce low end torque like a 16v kinda does. its because the 20v engine is designed in the head to make the most power up top ie; high rpm. 7a is not a rev friendly engine..... period. you can throw what ever you want at it, but intill you can get away from the over square stroke/bore, its kinda pointless. stock 7a being 81mm bore x 85.5mm stroke. that being said, unless you can get an 86mm or bigger piston, your bore/stroke remains over squared, also to add, 83m is pretty much the max you can bore the siamese 'A' blocks.

even if you had the 7a crank machined, used lightweaight h beam rods, light weight pistons, etc. your still gonna be 83mmx 85.5mm. add your kelford 30*/10.5's in the mix and your gonna be very disapointed. reason being, your not gonna turn a 7a to 10,000 rpms for long, and thats where you need it to be to make those kelfords, and the 20v to work to your advantage.

do this instead.....

20v blacktop block, 16v bigport head, mill the head, per our previous 'tear drop' conversations. get some nice flow porting, and throw some trd 310/11's in there. and pay close attention to your valvesprings, use the 1zz or yamaha shim underbuckets, and get your comp ratio around 13.5;1, setup for e85, or ron 91 with an octane additive. run your choice of aspiration setup, whether it be blacktop ITB's (largest oem) or weber DCOE 45's. the 16v bigport head will allow you to get that torque your obviously looking for, and the lightweight high comp oil squirter blacktop block will give you the lightweight freedom to rev, and make that big port head/cam combo work to your advantage.

even if you had the 7a crank machined, used lightweaight h beam rods, light weight pistons, etc. your still gonna be 83mmx 85.5mm. add your kelford 30*/10.5's in the mix and your gonna be very disapointed. reason being, your not gonna turn a 7a to 10,000 rpms for long, and thats where you need it to be to make those kelfords, and the 20v to work to your advantage.

do this instead.....

20v blacktop block, 16v bigport head, mill the head, per our previous 'tear drop' conversations. get some nice flow porting, and throw some trd 310/11's in there. and pay close attention to your valvesprings, use the 1zz or yamaha shim underbuckets, and get your comp ratio around 13.5;1, setup for e85, or ron 91 with an octane additive. run your choice of aspiration setup, whether it be blacktop ITB's (largest oem) or weber DCOE 45's. the 16v bigport head will allow you to get that torque your obviously looking for, and the lightweight high comp oil squirter blacktop block will give you the lightweight freedom to rev, and make that big port head/cam combo work to your advantage.

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

4agshoob wrote:allen... listen. theres a reason a 20v doesnt produce low end torque like a 16v kinda does.

This is completely untrue.

Stock largeport

Stock Blacktop

at 3k RPM the LP is putting 40 hp to the wheels. The blacktop is putting down 50.

From there the gap just grows.

7a is not a rev friendly engine..... period.

I suppose this is why both Hasselgren and Loynings offer 1.8 liter stroker options for high reving race motors?

but intill you can get away from the over square stroke/bore, its kinda pointless. stock 7a being 81mm bore x 85.5mm stroke. that being said, unless you can get an 86mm or bigger piston, your bore/stroke remains over squared, also to add, 83m is pretty much the max you can bore the siamese 'A' blocks.

Over square means the stroke is shorter than the bore. The 4A is over square. The 7A is under square.

More importantly under square does not mean it can't make power spinning fast, it's just a common trend that they tend to.

From Wikipedia

Despite their reputation as low-speed torque machines, some undersquare engines are designed for quite high speeds. The Honda Integra Type R's B18C5 engine has one of the highest redlines (8,400 rpm) of any production engine, yet features an undersquare design. The 2011 Ford Coyote engine is a modern undersquare engine with a 7,000 rpm redline.

The smallport is the more superior of the 16 valve heads.20v blacktop block, 16v bigport head

More importantly the 20 valve is a great platform with a ton of potential. The VVT is a huge asset which helps give the motor a broader powerband.

For an all out race engine the 16 valve may be superior but I'm pretty confident it's mostly just that the 16 valve has so much more development into it that it's accepted as the better head for a race motor.

and the lightweight high comp oil squirter blacktop block will give you the lightweight freedom to rev.

Squirters are not that important. The only other difference with the BT bottom end is the rods. If you really want lighter then you would be better off just buying aftermarket rods like the BC sportsman rods that weigh 415 grams whereas the BT rods are closer to 485 and really only a little lighter than other stock rods. Some aftermarket rods are even lighter.

http://forum.9000rpm.co.za/viewtopic.php?id=1964

The BC sportsman rods are actually about the same price as new OEM.

Re: 7AGE build

speedmaster wrote:v33sonata wrote:Gotya. I started a 7a 20v build already too. There is alot that goes into it. the 7a will rev just fine its the rods that become an issue. So you would want to upgrade them. I am using eagle hbeams from a Honda b16. What c/r are you thinking? are you using a BT or ST? You should get a hold of Barry at MRP they have done a bunch of 7a conversions along with others. They know their stuff!

yes, Barry gave his opinions as well, very helpful guy. Honda B16 H beams on the 7A crank? Why not go straight for 7A H beams? At the moment using 12.0CR CP pistons. Its a Blacktop.

at the time hbeam 7a rods were not made or were cheaply made. Are your pistons custom? It was hard to get a 11.1:1 out of mine would love to see your piston specs....

Re: 7AGE build

4agshoob wrote:allen... listen. theres a reason a 20v doesnt produce low end torque like a 16v kinda does. its because the 20v engine is designed in the head to make the most power up top ie; high rpm. 7a is not a rev friendly engine..... period. you can throw what ever you want at it, but intill you can get away from the over square stroke/bore, its kinda pointless. stock 7a being 81mm bore x 85.5mm stroke. that being said, unless you can get an 86mm or bigger piston, your bore/stroke remains over squared, also to add, 83m is pretty much the max you can bore the siamese 'A' blocks.

.

I can tell you from already having a 7age already this guy is totally wrong! plus from my sonic testing you can even go bigger on the pistons if you wanted too. The 7a with better rods will rev happily all day long. You'll get the HP from the head an better TQ with the 7a period! Nothing more to say!

Amen to that yoshimitsuspeed

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

The CP shelf pistons claim to be 12:1. They don't specify their dome or the combustion chamber used to come to that number. Most aftermarket piston companies mess that up. On the 20v pistons they also don't specify if that's for the ST or the BT which is important because they have different combustion chamber volumes.

I believe this is the 20v 12:1 piston.

I assume and hope your pistons were calculated for the 7A since that will increase your compression. I'm too lazy to do the math but 11:1 4A pistons would be much higher in the 7A.

With that said your pistons are completely flat which is good but you could gain a lot more compression if you gave it dome.

I believe this is the 20v 12:1 piston.

I assume and hope your pistons were calculated for the 7A since that will increase your compression. I'm too lazy to do the math but 11:1 4A pistons would be much higher in the 7A.

With that said your pistons are completely flat which is good but you could gain a lot more compression if you gave it dome.

Re: 7AGE build

Ya it's calculated on the 7a and a blacktop head. So I would assume that mine are more accurate. I'll be posting the specs up not under my thread

Re: 7AGE build

yoshimitsuspeed wrote:4agshoob wrote:allen... listen. theres a reason a 20v doesnt produce low end torque like a 16v kinda does.

This is completely untrue.

Stock largeport

Stock Blacktop

at 3k RPM the LP is putting 40 hp to the wheels. The blacktop is putting down 50.

From there the gap just grows.7a is not a rev friendly engine..... period.

I suppose this is why both Hasselgren and Loynings offer 1.8 liter stroker options for high reving race motors?but intill you can get away from the over square stroke/bore, its kinda pointless. stock 7a being 81mm bore x 85.5mm stroke. that being said, unless you can get an 86mm or bigger piston, your bore/stroke remains over squared, also to add, 83m is pretty much the max you can bore the siamese 'A' blocks.

Over square means the stroke is shorter than the bore. The 4A is over square. The 7A is under square.

More importantly under square does not mean it can't make power spinning fast, it's just a common trend that they tend to.

From WikipediaDespite their reputation as low-speed torque machines, some undersquare engines are designed for quite high speeds. The Honda Integra Type R's B18C5 engine has one of the highest redlines (8,400 rpm) of any production engine, yet features an undersquare design. The 2011 Ford Coyote engine is a modern undersquare engine with a 7,000 rpm redline.The smallport is the more superior of the 16 valve heads.20v blacktop block, 16v bigport head

More importantly the 20 valve is a great platform with a ton of potential. The VVT is a huge asset which helps give the motor a broader powerband.

For an all out race engine the 16 valve may be superior but I'm pretty confident it's mostly just that the 16 valve has so much more development into it that it's accepted as the better head for a race motor.and the lightweight high comp oil squirter blacktop block will give you the lightweight freedom to rev.

Squirters are not that important. The only other difference with the BT bottom end is the rods. If you really want lighter then you would be better off just buying aftermarket rods like the BC sportsman rods that weigh 415 grams whereas the BT rods are closer to 485 and really only a little lighter than other stock rods. Some aftermarket rods are even lighter.

http://forum.9000rpm.co.za/viewtopic.php?id=1964

The BC sportsman rods are actually about the same price as new OEM.

so without further questioning, can you guys please tell me the type of racing speedmaster is doing? i talk to this guy on the daily..... of off the forum.

1. different dyno's for comparison dont mean squat.

2. Hasselgren and loynings both use a 4a block with custom crank and pistons. not 7a specs. try 82.5mm x 84mm with varables. they damn sure are not pushing an over squared (longer bore than stroke) or undersquare (longer stroke than bore) like 82.5mm x 85.5mm. that throw just simply is too much for high rpm. harmonics prevent from power even being close at this ratio.

3. "For an all out race engine the 16 valve may be superior but I'm pretty confident it's mostly just that the 16 valve has so much more development into it that it's accepted as the better head for a race motor."................... exactly. pretty sure if hes using leford cams on both sides, vvti is not operational, are we all reading along here?

4. squirters are pretty important, if your revving a heavier rod engine (like the 485 gram stock bt rods, that are proven to hold 10k reliably) vs. if he wanted to dump money in aftermarket lightweight rods like the 415 gram your suggesting, and maybe do 10k rpm, but of course that would require a lightweight piston...then at that point hell its cheaper to just do a full block build isnt it?

again, i see your into the bench racing thing, kinda like you were in your whole larger is better gze throttle body design you tried to shoot me down on as well. btw, you ever get that worked out real world? didnt work did it...... or have you tried it? do **** guys, then make claims. real world, not bench racing.

Re: 7AGE build

guess due to being the only one in this thread with a 7age everyone should listen to me. the only reason ppl the the 16v for modding is cause parts are cheap and easy to get unlike the 20v its that's simple! your 20v 7a will be fun and different! and eat up all those 4a's lol. I had a 4age, 4agze and 7age 16v. so trust me when I say youll like the 7age 20v

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

4agshoob wrote:

so without further questioning, can you guys please tell me the type of racing speedmaster is doing? i talk to this guy on the daily..... of off the forum.

Nope but if it was vital to the conversation I would have hoped he would have told us.

4agshoob wrote:

1. different dyno's for comparison dont mean squat.

Although they can't be taken as gospel or guaranteed to be within a known accuracy they mean much more than squat. 20% variation between the two motors is significant and considerably higher than even the accuracy of the sloppiest dyno. More importantly I am confident I could find more that back up the trend.

4agshoob wrote:

2. Hasselgren and loynings both use a 4a block with custom crank and pistons. not 7a specs. try 82.5mm x 84mm with varables. they damn sure are not pushing an over squared (longer bore than stroke) or undersquare (longer stroke than bore) like 82.5mm x 85.5mm. that throw just simply is too much for high rpm. harmonics prevent from power even being close at this ratio.

Care to back that up with any math or science? Maybe some form of educated documentation that backs your theory?

It is my theory that Bore/Stroke ratio is oldschool edumacted talk for other things that cover a much broader scope that most can't or don't want to wrap their heads around. What exactly does the bore have to do with everything?

7A has a stroke of 85.5, the 3SGTE has a stroke of 86. According to you the 3S should be able to handle RPM better because it is a square engine. But why?

Now if we look at the unedumacated folks over on eng-tips the story looks a lot different. There are a lot of reasons behind why engineers would choose a particular ratio but none of them seem to have anything to do with optimum operating range. The only thing mentioned that has anything to do with RPM is piston speed and that has nothing to do with bore or the bore stroke ratio. According to the general consensus in the threads below and my personal belief is that the 3S and 7A would have similar limits based largely on piston speed. If we use some of the numbers thrown around in there we can say that either bottom end should do fine up to about 9500 RPM.

http://www.eng-tips.com/viewthread.cfm?qid=110748

http://www.eng-tips.com/viewthread.cfm?qid=85349

http://www.eng-tips.com/viewthread.cfm?qid=122910

4agshoob wrote:

3. "For an all out race engine the 16 valve may be superior but I'm pretty confident it's mostly just that the 16 valve has so much more development into it that it's accepted as the better head for a race motor."................... exactly. pretty sure if hes using leford cams on both sides, vvti is not operational, are we all reading along here?

He mentioned what cams he currently has but I don't remember him saying he was set on using them, what his power goals were or exactly how he planned on getting there.

I would try to keep the VVT as long as possible personally. Kelford has some pretty big cams that still handle VVT.

Even without the VVT the 20v heads still have better port angles, better valve angles and some other advantages that the 16 valve don't have.

They also have what some consider to be some disadvantages like the fifth valve inhibiting airflow to some degree but there is a lot that can be done and there are a lot of 5 valve sport bike motors and other motors that make excellent power per displacement.

4agshoob wrote:

4. squirters are pretty important, if your revving a heavier rod engine (like the 485 gram stock bt rods, that are proven to hold 10k reliably) vs. if he wanted to dump money in aftermarket lightweight rods like the 415 gram your suggesting, and maybe do 10k rpm, but of course that would require a lightweight piston...then at that point hell its cheaper to just do a full block build isnt it?

He is talking about mixing and matching parts from multiple different motors which will require custom fab and machining. The cost of rods and pistons would be small in comparison.

again, i see your into the bench racing thing, kinda like you were in your whole larger is better gze throttle body design you tried to shoot me down on as well. btw, you ever get that worked out real world? didnt work did it...... or have you tried it? do **** guys, then make claims. real world, not bench racing.

Lol, hardly. I have done quite a lot and continue to do so. I have also helped a number of people with successful builds that I have learned from as well.

Unfortunately I don't have the time and money to try everything I want all at once. There is a difference between bench racing and using math, science, physics, intake, exhaust and engine theory, the powers of the internets and personal experience to theorize about how something will work before testing it.

You like to give me a hard time but at least I back my opinions and my theories with well educated sources.

- oldeskewltoy

- Club4AG MASTER

- Posts: 2184

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: 7AGE build

I happen to know for a fact that Loynings does use some 7A blocks... and they have built a few of those with 91mm stroke!!!

Not 4AG... but as far as throttle body size... this Toyota GR1 is running a 40mm restrictor, and makes nearly 440hp

Not 4AG... but as far as throttle body size... this Toyota GR1 is running a 40mm restrictor, and makes nearly 440hp

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

oldeskewltoy wrote:Not 4AG... but as far as throttle body size... this Toyota GR1 is running a 40mm restrictor, and makes nearly 440hp

But how much would it make without restriction?

More importantly the original discussion was about the GZE and due to the way fixed displacement SCs work it's all based off pressure ratios. If you are running a 2:1 pressure ratio at sea level you would be making about 14.7 PSIG boost. If you had a 1 PSI pressure drop before the SC you would only make 12.7 PSIG boost.

On top of that since the pressure ratios would be the same your outlet temps would be the same even though you were making 2 PSI less boost. For this reason SC cars are much more susceptible to pressure drops than NA or turbo motors.

- oldeskewltoy

- Club4AG MASTER

- Posts: 2184

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: 7AGE build

apologies for the thread diversion......

Without restrictor.... with ITB's... about 15hp more @ peak........ but 40 less between 4500 and 8000

The restrictor engine is faster on the track because it has more power in the middle of the powerband...

yoshimitsuspeed wrote:oldeskewltoy wrote:Not 4AG... but as far as throttle body size... this Toyota GR1 is running a 40mm restrictor, and makes nearly 440hp

But how much would it make without restriction?

Without restrictor.... with ITB's... about 15hp more @ peak........ but 40 less between 4500 and 8000

The restrictor engine is faster on the track because it has more power in the middle of the powerband...

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: 7AGE build

oldeskewltoy wrote:

Without restrictor.... with ITB's... about 15hp more @ peak........ but 40 less between 4500 and 8000

Not exactly a fair comparison since the whole intake design was changed.

Whatever the case the main point is that the pressure differential is multiplied in a SC setup.

Re: 7AGE build

oldeskewltoy wrote:I happen to know for a fact that Loynings does use some 7A blocks... and they have built a few of those with 91mm stroke!!!

Not 4AG... but as far as throttle body size... this Toyota GR1 is running a 40mm restrictor, and makes nearly 440hp

right, but are they (7a) running 10k rpm, which means it will have to have an even higher rev tolerance to sustain a 10k rpm redline, right? mis shifts and everything. and what do those engines run price wise?

and on to the throttle body/gze thing, thats exactly my point. smaller/velocity/etc. bigger is not always better. putting a 90mm throttle body before your 20% over driven sc12, isnt gonna net you anymore power than running a 63mm TB, and a matched 2.5" inlet pipe. bottle necking a 3" tb into an sc12, makes no difference.

Re: 7AGE build

guys lets stop ruining this poor guys thread.

- speedmaster

- Club4AG Expert

- Posts: 234

- Joined: Tue Jan 22, 2013 9:44 pm

- Location: Malaysia and Brunei

- Contact:

Re: 7AGE build

No worries. Im cool. Just reading it slowly and trying to understand

Visit my FB fan page at https://www.facebook.com/speedmasteracing

-

MisterJerk

- Club4AG Pro

- Posts: 582

- Joined: Wed Jan 09, 2013 6:10 pm

Re: 7AGE build

oldeskewltoy wrote:I happen to know for a fact that Loynings does use some 7A blocks... and they have built a few of those with 91mm stroke!!!

I wonder what the limits of the 7a block are in regards to stroke. The 1zz crank is 91.5mm. MRP and Spool stroker kits are both 90mm.

To the OP: since you have a 1zz crank and a 7a block

the crank journals, spacing, other important measurements match the block? Have you tried to set the 1zz crank in the block to eyeball it?

RTFM!!!!!!!!!!! --> http://www.aeu86.org/technical/

- oldeskewltoy

- Club4AG MASTER

- Posts: 2184

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: 7AGE build

4agshoob wrote:

right, but are they (7a) running 10k rpm, which means it will have to have an even higher rev tolerance to sustain a 10k rpm redline, right? mis shifts and everything. and what do those engines run price wise?

Most engine guys... would rather make the power lower in the rpm band if they can. Twisting a 4AG well above 10,000 is no longer necessary. Most of the engine builders are making their peak power(260+hp) at or just under 10,000 these days. These engine are also long rod 4AGs(127.5mm)

Most of the "tall block" (Loyning speak for a 7AGE) builds only twist to about 8500.. maybe 9000, and make upwards of 280hp and 175/#/ft

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Re: 7AGE build

oldeskewltoy wrote:4agshoob wrote:

right, but are they (7a) running 10k rpm, which means it will have to have an even higher rev tolerance to sustain a 10k rpm redline, right? mis shifts and everything. and what do those engines run price wise?

Most engine guys... would rather make the power lower in the rpm band if they can. Twisting a 4AG well above 10,000 is no longer necessary. Most of the engine builders are making their peak power(260+hp) at or just under 10,000 these days. These engine are also long rod 4AGs(127.5mm)

Most of the "tall block" (Loyning speak for a 7AGE) builds only twist to about 8500.. maybe 9000, and make upwards of 280hp and 175/#/ft

point taken, thank you. the only reason i brought the high rpm remarks into pla are for the fact of mister speeds cam profiles he'd listed... kelford 30* w/ around 10-11mm of lift. obviously no one is realizing these cam profile benefits at anything lower than 7000 rpms, especially where torque is in play.

Re: 7AGE build

in looking into this situation i have to ponder this....

what about placing a 7a crank into a 4a block using 4a rods with shorty pistons...... in other words... i guess im saying:

82.5mm x 85.5mm.. i guess this would just be a 7a, but without the longer rods..... meaning with the shorter rods, torque wouldnt be ideal, but youd have a rev happy engine 'stroked".

what about placing a 7a crank into a 4a block using 4a rods with shorty pistons...... in other words... i guess im saying:

82.5mm x 85.5mm.. i guess this would just be a 7a, but without the longer rods..... meaning with the shorter rods, torque wouldnt be ideal, but youd have a rev happy engine 'stroked".

Re: 7AGE build

7A crank will not fit and the 4A rods will not work with the 7A crank because of the rod journals are bigger. What has been discussed before on the old forums was using a 4A crank in a 7A block, 15mm longer rods than that of a 4A, and high comp pistons. You will have a rev happy, long rod motor if this is your goal. It is essentially a "destroked 7A"

4agshoob wrote:in looking into this situation i have to ponder this....

what about placing a 7a crank into a 4a block using 4a rods with shorty pistons...... in other words... i guess im saying:

82.5mm x 85.5mm.. i guess this would just be a 7a, but without the longer rods..... meaning with the shorter rods, torque wouldnt be ideal, but youd have a rev happy engine 'stroked".